Categories

Qingdao Xinri Machinery Manufacturing Co., Ltd. >> EPS Cement Sandwich Panel Steel Prefabricated House/Villa

EPS Cement Sandwich Panel Steel Prefabricated House/Villa

| Price: | US $ 40-45/Square Meter |

|---|---|

| Trade Terms: | FOB,CFR,CIF |

| Min Order: | 100/Square Meter |

| Pay Type: | L/C,T/T |

Modular Prefab luxury Living Villa

Modular Prefab luxury Living VillaPrefab villa is widely used in remote areas as resident houses, construction accommodations, office, classroom, clinics, oil field camps, offshore accommodation, labor camps, guardrooms, container house and mobile house.

Advantages:

The prefab villa has advantages in easy installation, low time and labor cost, being economical and environmentally friendly.

Main Frame Work:

The main frame work is light steel structure and the wall&roof panel is ALC (aerated lightweight concrete) / AAC (autoclaved aerated concrete) panel.

1.Rough house(blank houses) without decoration and inside matching facilities

Main structure of Light Gauge Steel with Exterior wall and Floor made of ALC panel of 150mm or 200mm thickness+Interior wall and Roof made of ALC panel of 120mm thickness

2.Refined decoration Villa(completetly finished house)

Main structure of Light Gauge Steel with Exterior wall and Floor made of ALC panel of 150mm or 200mm thickness+Interior wall and Roof made of ALC panel of 120mm thickness,with water-proof putty and latex paint decorations.

With all inside matching facilities such as:

Other fittings: toilet,washbasin,shower,kitchen etc.

Ceiling material: MGO board/gypsum board

Door: steel security door/WPC or wooden door

Floor/foundation material: laminate flooring/wooden/PVC carpet

Window: aluminum alloy/PVC

Roofing: ALC panel/steel roofing/asphalt shingle or aspirant shingle(steel shingle painting with colorful stone powders on the surface)

Technical Parameter1)Wind resistance: Grade 11(wind speed≤111.5km/h)

2)Earthquake resistance: Grade 7

3)fire proof: B2 grade

Materials:

1)Material: Light steel structure, steel material Q235

2)Surface working: sand blasting, epoxy basic painting 55μm, final vinyl acrylic painting 55μm thick

3)Floor

1)External wainscot: Flat galvanized color steel sheet, 0.4mm thickness

2)Floor structure: Girder made of 4mm steel. The purlin is square tube dimension 60x40x1.5mm.

3)Warm proof insulation layer: 75mm rock wool

4)Floor: 15mm thick plywood panel for general room; 20mm thick cement board for WC and kitchen

1.5mm PVC floor leather for living rooms floor; 1.5mm anti-slip aluminum board for toilet floor.

5)Permitted loading: 2.0KN/m2

6)Coefficient of thermal conductivity: K=1.1W/ m2K

4)Ceiling

1)Roof exterior layer: 1.2mm stamping steel plate,epoxy painting

2)Warm proof insulation filling: 75mm rock wool between wooden purlins;

3)Inner wainscot: 9mm MDF laminated decorative panel or 10mm glass magnesium fire-proof board

4)Permitted live loading: 0.5 KN/m2

5)Coefficient of thermal conductivity: K=0.55W/ m2K

6)Roof water drain: 4 PVC rainwater pipes in the corner pillars, diameter 50mm

5)Walls

1)Panel width: 1150mm; panel total thickness: 75mm

2)External layer: Galvanized and painted (29μm) color steel sheet 0.5mm

3)Internal layer: Galvanized and painted (29μm) color steel sheet 0.5mm.

4)Warm proof insulation filling: 75mm EPS or rock wool or 50mm PU panel

5)Insulation density: EPS is 12kg/ m3;rock wool is 120kg/ m3;PU is 45kg/ m3

6)Permitted loading: 0.6KN/m2

7)Coefficient of thermal conductivity: K=0.442W/mk

6)Door

External door: sandwich panel door with opening dimension 850*2100mm, furnished with a cylinder lock with 3keys. Door frame is made of aluminum, 50mm thick EPS insulation foam.

7)Windows

Window material: PVC, white color, dimension 1130*1000mm, glass thickness: 3mm, aluminum alloy edge cover, sliding window with fly screen.Or PVC windows with rolling shutter.

| Prod Model: | X-p |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Material: | Sandwich Panel |

| Usage: | Workshop |

| Certification: | BV |

| Customized: | Customized |

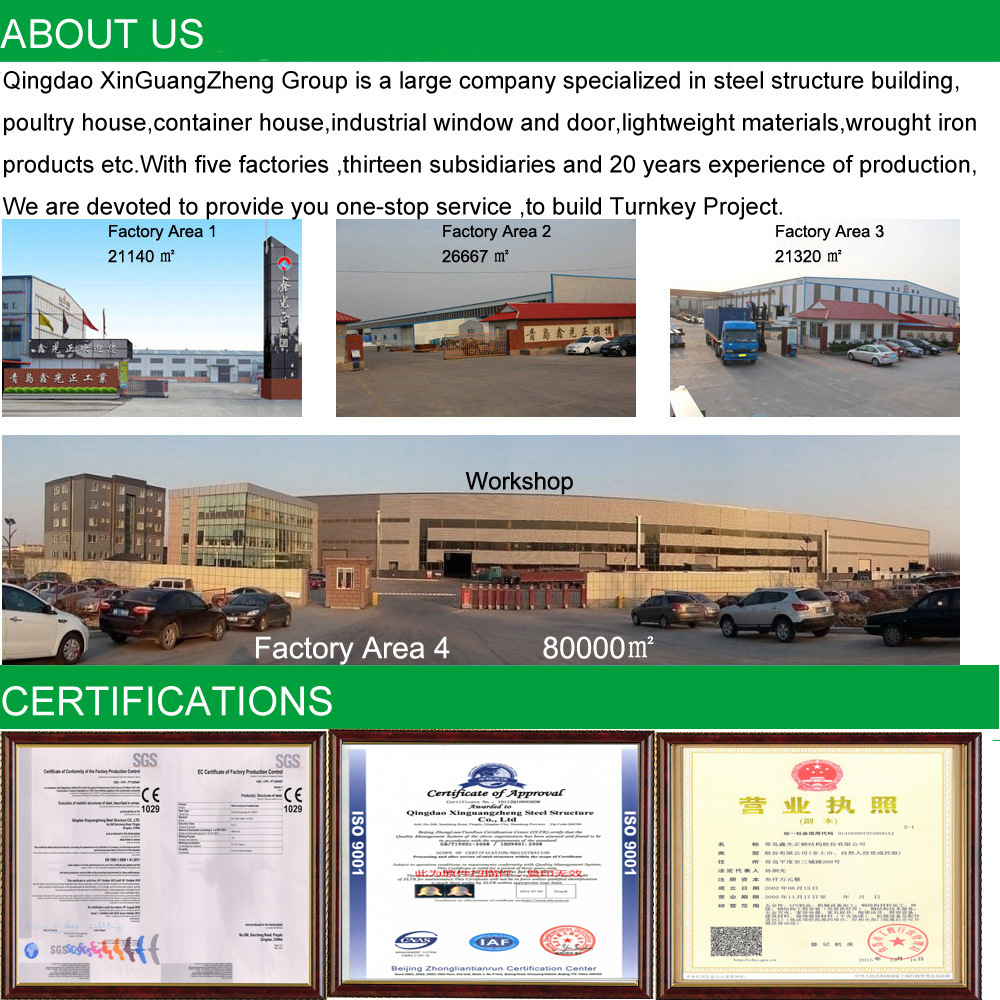

Qingdao Xinri Machinery manufacturing Co., Ltd was established since 2007, and be a subsidiary of Qingdao Xinguangzheng Group Company. (Qingdao Xinguangzheng steel structure company)

It is located in beautiful coastal city Qingdao (Shandong Province)enjoying convenient transportation access.

Qingdao Xinri Poultry Co., Ltd is a large company specialized in designing, modeling, manufacturing and installing chicken cage and steel structure chicken house project.

We have been undertaking a lot of steel structural projects and chicken farm around the world, and won widespread praise from customers of domestically and overseas.

As one of the leading poultry farm manufactures, our workshop area covers more than 50, 000 square meters with beautiful environment, and the advanced processing equipment, good technological innovative ability, great capacity of production and processing in China. We also have established a good cooperative relationship with many worldwide companies.

Our company has passed ISO 9001: 2008, TUV Authentication, and CE.

Our principle is"To accomplish our customers' goals with honor and dignity. We firmly believe that, with the spirit of consistent pursuit of technological development and good quality, we shall provide you not only with exquisite products but also more valued service, according to our professional knowledge and design of chicken products for the customers.

Qingdao Xinri Poultry Co., Ltd will make an outstanding contribution to promote the development of world Poultry Industry. Sincerely welcome customers worldwide to establish long-term business relationships based on mutual benefits.

It is located in beautiful coastal city Qingdao (Shandong Province)enjoying convenient transportation access.

Qingdao Xinri Poultry Co., Ltd is a large company specialized in designing, modeling, manufacturing and installing chicken cage and steel structure chicken house project.

We have been undertaking a lot of steel structural projects and chicken farm around the world, and won widespread praise from customers of domestically and overseas.

As one of the leading poultry farm manufactures, our workshop area covers more than 50, 000 square meters with beautiful environment, and the advanced processing equipment, good technological innovative ability, great capacity of production and processing in China. We also have established a good cooperative relationship with many worldwide companies.

Our company has passed ISO 9001: 2008, TUV Authentication, and CE.

Our principle is"To accomplish our customers' goals with honor and dignity. We firmly believe that, with the spirit of consistent pursuit of technological development and good quality, we shall provide you not only with exquisite products but also more valued service, according to our professional knowledge and design of chicken products for the customers.

Qingdao Xinri Poultry Co., Ltd will make an outstanding contribution to promote the development of world Poultry Industry. Sincerely welcome customers worldwide to establish long-term business relationships based on mutual benefits.