Categories

Mayflay Machinery (Huizhou) Co., Ltd. >> Large Abrasive Blasting Cabinet, Model: Ms4080

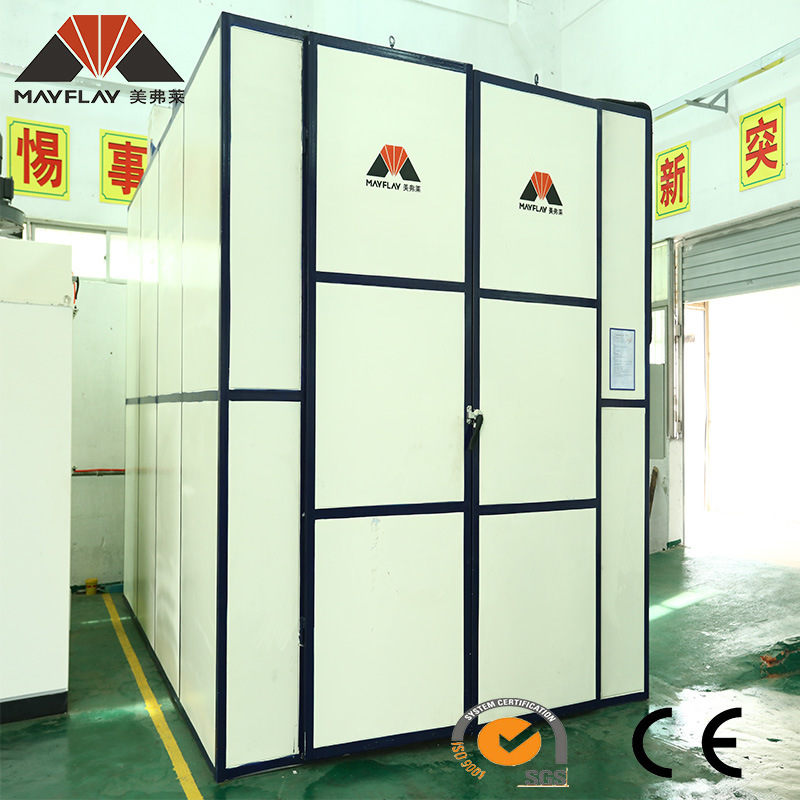

Large Abrasive Blasting Cabinet, Model: Ms4080

| Price: | Negotiable/Set |

|---|---|

| Min Order: | 1/Set |

| Pay Type: | L/C,T/T,Western Union,Paypal,Money Gram |

Sand Blasting Room Main Description:

1. Shot Blasting Room is ideal for the large-scale structures, widely used in blasting of hulls, stoves,boilers and wind power parts, etc.Large structures can move inside the Blast Room on work cars sliding on rails.

2. Mainly composed with the Blasting Room, Air Blasting System, Sand Circulatory System, Dehumidify System and Dust Collector.

3.Shot blasting room system is widely used in shipbuilding industry, military, and engineering machinery, petrochemical machinery, hydraulic machinery and bridge structures, locomotives and etc. and is suitable for large metal structure before painting surface blast cleaned and shot peening treatment .

4.Sandblasting processing can thoroughly clean the surface of work piece of welding slag, rust, descaling, grease, improve surface coating adhesion, achieve long term anticorrision purpose. In addition, using shot peening treatment, which can eliminate the work piece surface stress and improve the intensity.

Sand Blasting Room Advantages :

1.Our company provides of shot blasting room system has low failure rate, maintenance is simple, high technical content, good quality, high efficiency, long service life and working environment is good wait for an advantage.

2.Abrasive Blast Room are designed and fabricated according to the size requested by the customer.

3.They may have one or two main doors for material access. The structure of the room may consist either of steel walls or color sandwich panels with polyurethane insulation.

4.The internal walls are lined with wear-proof rubber. The floor is made of steel grating which cover the automatic recovery system for abrasives. The material handling can be done by trolleys or by overhead crane.

5.The room includes pedestrian access doors, lighting system, fixed walkways or mobile platforms for the sand-blasting of the higher parts, manual shot-blasting unit, ventilation and dust extraction system, and self-cleaning dry cartridges dust collector.

6.The shot-blasting unit is fitted with remote control and abrasive automatic loading, and is supplied complete with all the operator work and protection equipment. In case the customer has already an available room, we also can supply the design and the equipment to carry out the shot-blasting operation.

Sand Blasting Room Application Industry:

1. All kinds of profiled steel .

2. Steel plate

3.Sheet metal parts

4.Heavy metal parts ,machine body etc.

Sand Blasting Room Advantage:

1.Adopt elevator shot material recycling system to meet the Max. 15 guns recover

2.Integrated design, small floor space

3.Using advanced control system ,In accordance with SAE AMS - 2430 standard

4.Using peach-shaped double-tank shot peening system, can achieve continuous uninterrupted shot peening

5.Dust catcher using advanced secondary filtration ,dust emission less than 1mg/m³

6.Assembly power is about 7kw, more energy efficient

Sand Blasting Room Picture:

Sand Blasting Room Technology Data:

MS-4080 Detachable Sandblasting Room Technology Data | ||||

No. | Name | Standard Data | Optional Data | |

1 | Shot Room | Room Length (MM) | 8000 | 6000,4000 |

Room Width (MM) | 4000 |

| ||

Room Height (MM) | 3000 |

| ||

Room Door Width (MM) | 2500 |

| ||

Room Door Height (MM) | 2380 |

| ||

Workpiece Max. Size (MM) | 2000*2400*2200(L*W*H) |

| ||

2 | Pressure System | Pressure tank capability | 280L |

|

Shot gun number | 1 PC gun (Standard configuration) | Customers Requirement | ||

Steel shot flow adjust way | Manual adjust flow+pneumatic valve opening and closing control |

| ||

Blasting pressure adjust range | 4-6bar |

| ||

3 | Shot recovery system | Steel shot recovery way | Wind recovery | Elevator recovery |

Max steel shot recovery capacity | 250kg/min |

| ||

Storage silo | Storage capacity | 1.7T |

| |

4 | Dust collector | Secondary filtering device |

| |

Dust remove air flow | 2250m3/h |

| ||

Dust emission | ≤5mg |

| ||

Fan power | 7.5kw |

| ||

5 | Electric cabinet | Working pattern | manual |

|

Optional part | Vibration sieve | 0.55kw |

| |

Automatic door | Pneumatic |

| ||

6 | Compressed air demand | Air supply amount | 10Nm3/h(blasting pressure reach 5bar) |

|

Air supply pressure | 5-7bar |

| ||

7 | Install power | Total power | 8.5kw | 9.05kw(with vibrating screen) |

8 | The first adding steel shot quantity | 1000kg |

| |

9 | Environmental indicator | Dust emission | ≤5mg/m3 |

|

Noise | <85dB(A) |

| ||

10

| Machine color | Main Body | 7035(ice-gray) |

|

Maintenance door and guardrail | RAL1023(Yellow) |

| ||

11 | Production | Supply voltage | 380V±10%,3-phase,50HZ ±5% |

|

Environment temperature | 0ºC-40ºC,relative humidity ≤90% |

| ||

Air pressure | 0.7MPa±0.1MPa |

| ||

12 | Machine size | L*W*H | 8500X5750X4390 |

|

13 | N.W | 18T | ||

Sand Blasting Room Main Parts Details:

Mayflay Other Series Machine:

About Us:

| Prod Model: | MS4080 |

|---|---|

| Name: | Large Abrasive Blasting Cabinet |

| PLC: | Siemens |

| Ei Electromagnetic Flow Valve: | American Ei |

| Automatic Flow Control Valves: | Belgium Belimo |

| Shot Peening System: | China Mayflay |

| Air Proportional Valve: | Italy Metalwork |

| Vibrating Screen: | American Sweco |

| Servo Robot: | Japan Mitsubishi |

| Dust Emission: | Less Than 1mg/M3 |

| Touch Screen: | Touch Screen |

| Application: | Surface Cleaning |

| Fuel: | Air |

| Type: | Sand Blasting Room |

Introduction:

Mayflay Machinery (Huizhou) Co., Ltd is a research and development, design, production, market, installation, service and trade in one diversified enterprise.

We own CNC bending machine, CNC cutting machine, sawing machine, drilling machine, lathe, milling machine, shot peening /shot blasting test equipment, shot blasting /shot peening laboratory, advanced processing equipment and measuring instruments.

Development History

In 2010, Kunshan Mayflay Machinery Co., Ltd is established. We design and produces sand blasting machine, shot peening machine and shot blasting machine.

In 2016. Mayflay Machinery (Huizhou) Co., Ltd is established. We still produce and sell sand blasting machine, shot peening machine and shot blasting machine. Expand China marketing and open international marketing.

Enterprise Concept:

Integrity, People First, Quality First, Win-Win.

Product Concept:

Survive on Quality, Promote sales to stimulate production, Continuous innovation.

Enterprise Policy:

Take the market as the guidance, Take the technology as the core, Take quality as guarantee, Take customer satisfaction as the mission

Main Products:

Our main products are shot blasting machine, shot peening machine, sand blasting machine, sand blasting room, dust collector, steel shot, spare parts etc.

Shot blasting machine inlcuding below:

1. Crawler shot blasting machine, Model: MB

2. Chain through shot blasting machine, Model: MCT

3. Turntable shot blasting machine, Model: MDT1, MDT2, MDT5

4. Hook/Hanging type shot peening machine, Modle: MHB2

5. Mesh through shot blasting machine, Model: MND

6. Roller through shot blasting machine, Model: MTR

Shot peening machine including below:

1. Turntable shot peening machine, Model: MRT2, MRT4

2. Threaded column shot peening machine: Model: MSH

3. Station shot peening machine, Model: MST1, MST4

4. Robot shot peening machine, Model: MST4-15L2-1

Sand blasting machine including below:

1. Manual sand blasting machine

2. Automatic sand blasting machine

Sand blasting room including below:

1. Manual sand blasting room

2. Automatic sand blasting room

Dust collector including below:

1. Wet type dust collector

2. Dry type dust collector

Steel shot including below:

1. Wire cutting steel shot

2. Casting steel shot

3. Aluminum

4. Other kinds etc.

Application:

1. Cleaning area: Casting, forging, heat treatment, before industrial machinery equipment coating surface cleaning.

2. Intensify area: Shipping, space flight and aviation, rail transport, bridge industry, spring industry, thermal power generation, wind power generation, Oil Drilling, automobile industry surface intensify processing.

3. Industrial dedusting area etc.

Mayflay Machinery (Huizhou) Co., Ltd is a research and development, design, production, market, installation, service and trade in one diversified enterprise.

We own CNC bending machine, CNC cutting machine, sawing machine, drilling machine, lathe, milling machine, shot peening /shot blasting test equipment, shot blasting /shot peening laboratory, advanced processing equipment and measuring instruments.

Development History

In 2010, Kunshan Mayflay Machinery Co., Ltd is established. We design and produces sand blasting machine, shot peening machine and shot blasting machine.

In 2016. Mayflay Machinery (Huizhou) Co., Ltd is established. We still produce and sell sand blasting machine, shot peening machine and shot blasting machine. Expand China marketing and open international marketing.

Enterprise Concept:

Integrity, People First, Quality First, Win-Win.

Product Concept:

Survive on Quality, Promote sales to stimulate production, Continuous innovation.

Enterprise Policy:

Take the market as the guidance, Take the technology as the core, Take quality as guarantee, Take customer satisfaction as the mission

Main Products:

Our main products are shot blasting machine, shot peening machine, sand blasting machine, sand blasting room, dust collector, steel shot, spare parts etc.

Shot blasting machine inlcuding below:

1. Crawler shot blasting machine, Model: MB

2. Chain through shot blasting machine, Model: MCT

3. Turntable shot blasting machine, Model: MDT1, MDT2, MDT5

4. Hook/Hanging type shot peening machine, Modle: MHB2

5. Mesh through shot blasting machine, Model: MND

6. Roller through shot blasting machine, Model: MTR

Shot peening machine including below:

1. Turntable shot peening machine, Model: MRT2, MRT4

2. Threaded column shot peening machine: Model: MSH

3. Station shot peening machine, Model: MST1, MST4

4. Robot shot peening machine, Model: MST4-15L2-1

Sand blasting machine including below:

1. Manual sand blasting machine

2. Automatic sand blasting machine

Sand blasting room including below:

1. Manual sand blasting room

2. Automatic sand blasting room

Dust collector including below:

1. Wet type dust collector

2. Dry type dust collector

Steel shot including below:

1. Wire cutting steel shot

2. Casting steel shot

3. Aluminum

4. Other kinds etc.

Application:

1. Cleaning area: Casting, forging, heat treatment, before industrial machinery equipment coating surface cleaning.

2. Intensify area: Shipping, space flight and aviation, rail transport, bridge industry, spring industry, thermal power generation, wind power generation, Oil Drilling, automobile industry surface intensify processing.

3. Industrial dedusting area etc.